As someone who has not worked in a professional role that required much, if any, electronics experience I was always worried lacking this skill would hold me back. This motivated me to develop these skills in my free time, leading to the projects highlighted here

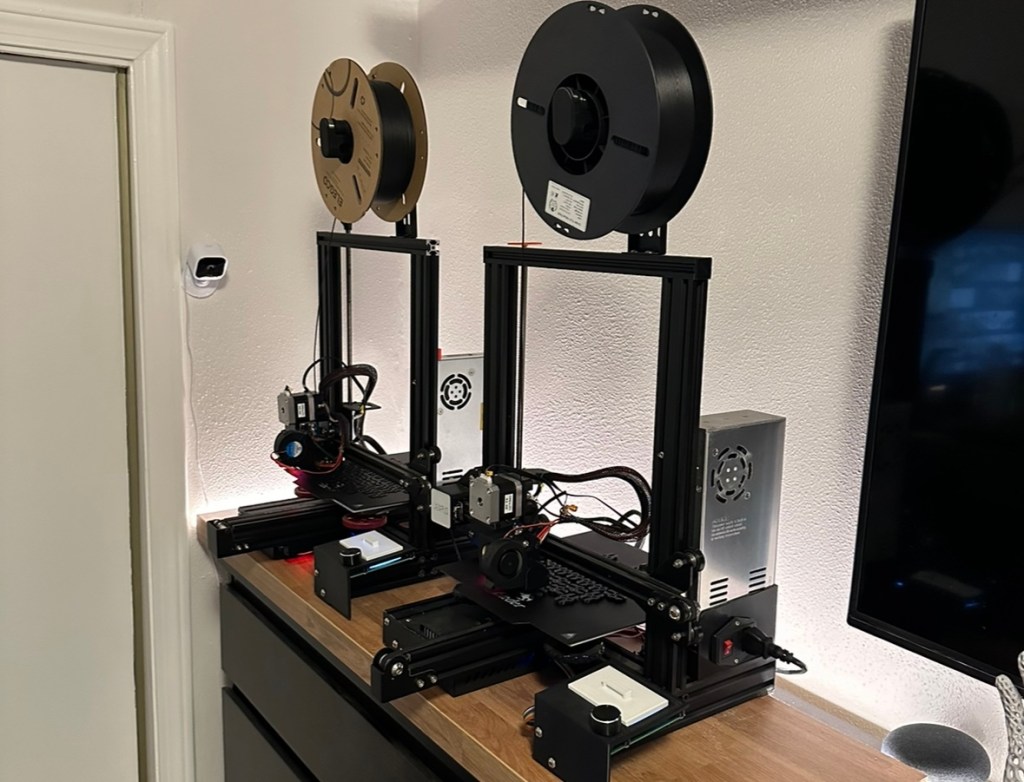

3D Printers

My foray into 3D printing started in 2019. I was making a lot of small leather goods and someone online was talking up 3D printing as a way to make wet molds. I purchased an Ender 3 to try, and was hooked on how much utility it brought to leatherworking and my other hobbies. After a while I had more than one filament printer and a resin printer in my office. Eventually, when using these budget 3D printers, you start to recognize their shortcomings. To avoid frustration I learned how to write Marlin code and compile firmware to improve the performance of the printer. I learned how to add new sensors for faster and more accurate bed leveling. I even got pulled into the world of Raspberry Pis and remote printer management. If I was asked to suggest a maker starting point, it would be 3D printing.

Engraving CNC Router

The 3D printed CNC router was a project spun up by Indystry in 2020. It sought to bring a level of precision machining to hobbyist. As someone who was already in the woodworking world with a desire to improve the quality of my work, but not in a place to spend thousands of dollars, this was a great place to start. This project is well designed, the build process is well explained, and there’s a large community of makers online willing to help get newcomers up and running. I used this small CNC router for 3 years until I needed to scale up to a larger volume and upgraded to a Shapeoko 4 XXL. This project pushed me to learn the Arduino IDE, Open GRBL, soldering, and wire sizing.

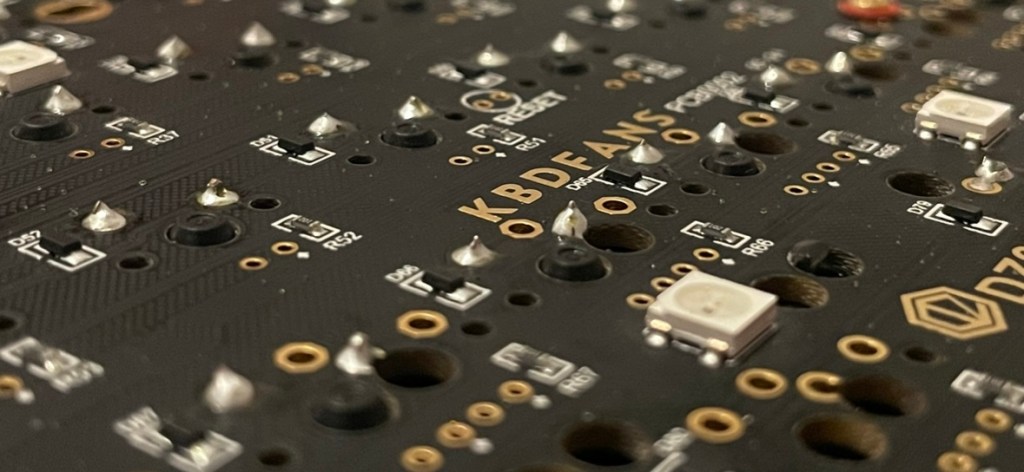

Mechanical Keyboards

Once I had experience wiring, soldering, and testing my connections I set out to design and build something I use everyday, a computer keyboard. Like previous projects, this hobby is relatively well explored and there are plenty of resources available to troubleshoot and guide you through the process. In 2021, after much research, I ordered a PCB, switches, keycaps, and I cut my own walnut case. I hand soldered all the switches to the board, compiled new firmware to match my layout, and made a custom USB-C cable to match the keycaps. The finished keyboard can be seen in the gallery below or the on the Woodworking page.

Guitar Amps

In early 2023 I was challenged with building a piece of furniture that captured the style of an established space, while also adding a guitar amp to the room. This was a unique opportunity to use a combination of my skills in one project. I took an existing guitar amp, designed a new housing for all the circuitry, bent sheet metal to enclose everything and mounted it to a small credenza I built. The final product is the culmination of so many years of learning, from the outer hardwood box down to the tiny resin printed knobs. To this day its one of my proudest creations. The finished credenza can be seen in the gallery below or the on the Woodworking page.

Home Lab

At the end of 2023 I started to feel confident about my understanding of the Raspberry Pis, so decided to build my own computer. The purpose of this build was to add a network attached storage (NAS) device to our new home. This would give us a place to safely back up our data. This project quickly evolved into a home lab. I’m now hosting a Plex server, running Home Assistant for home automation, Vikunja to organize everyone in my home’s schedule, and Mealie to store our recipes. This all runs on 10 inch rack alongside a pair of souped-up Dell Optiplexes.